Types of solar panels: As the world shifts towards renewable energy, solar power stands out as one of the cleanest and most abundant sources. At the core of this revolution are solar cells and solar modules (panels). This blog explores their components, how they are made, and why efficiency and capacity are crucial factors in solar energy systems.

What is a Solar Cell?

A solar cell, also known as a photovoltaic (PV) cell, is a device that converts sunlight directly into electricity using the photovoltaic effect.

🔹 Made from semiconductors, mostly silicon

🔹 Works by absorbing photons and releasing electrons

🔹 One cell typically produces about 0.5V to 0.6V

What is a Solar Module (Solar Panel)?

A solar module is a collection of solar cells arranged and encapsulated together to form a panel.

🔹 Usually contains 60, 72, or 144 cells

🔹 Generates 30V to 50V per panel

🔹 Multiple modules form a solar array

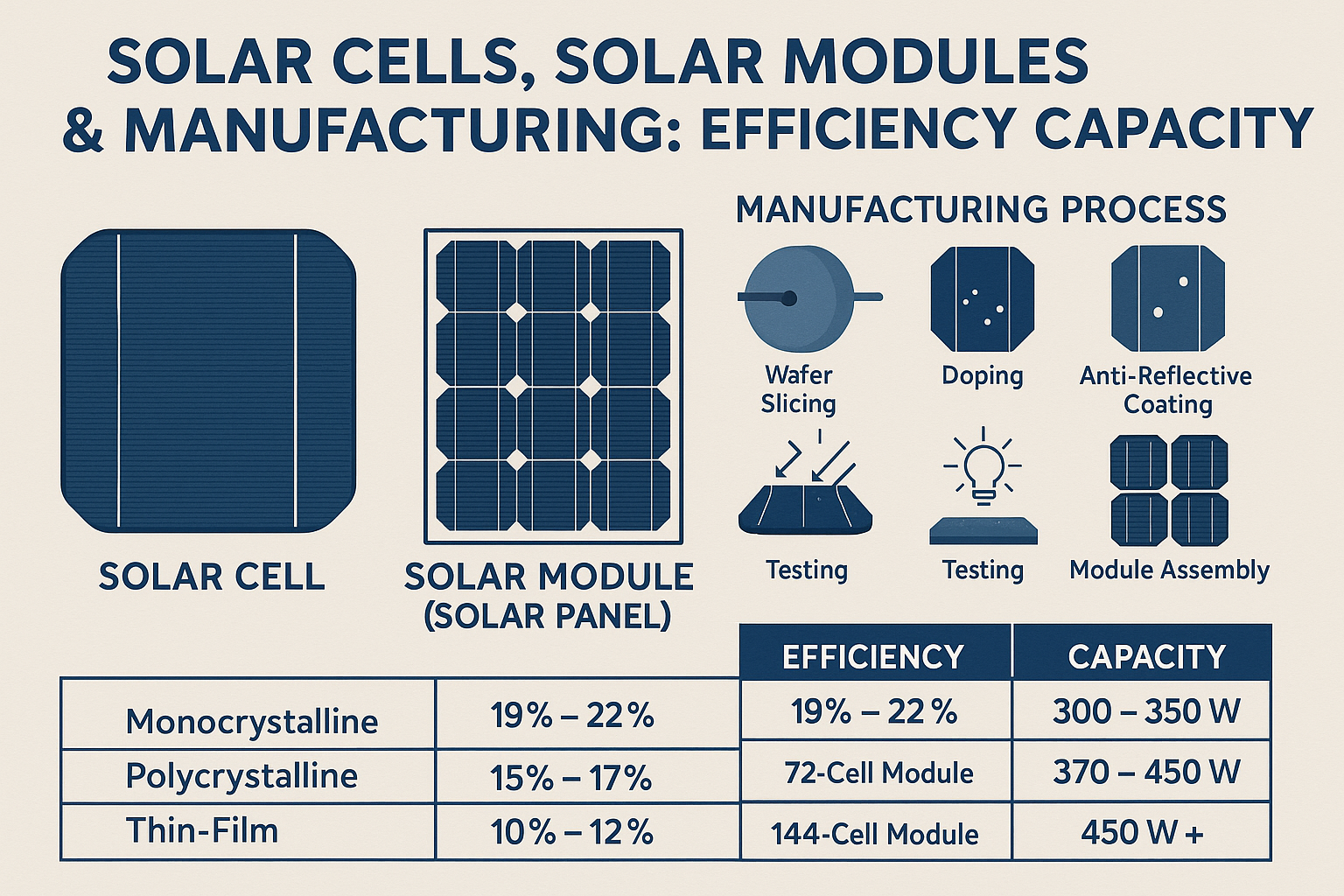

How are Solar Cells and Modules Manufactured?

1. Ingot Formation

- High-purity silicon is melted and shaped into cylindrical (monocrystalline) or square (polycrystalline) ingots.

2. Wafer Slicing

- Ingots are sliced into thin wafers (~150–200 microns thick).

3. Doping & Junction Creation

- Wafers are treated with phosphorus or boron to create p-n junctions that generate electricity.

4. Anti-Reflective Coating

- Blue or black coating reduces sunlight reflection and increases light absorption.

5. Metal Contacts

- Silver or aluminum contacts are added to collect the electrons and form circuits.

6. Cell Testing

- Each cell is tested for efficiency, voltage, and defects.

7. Module Assembly

- Cells are connected, laminated in EVA, sealed with glass and backsheet, framed with aluminum.

8. Final Testing

- Flash testing, EL testing, and reliability checks before dispatch.

1. Crystalline Silicon (c-Si) Solar Cells

-

Material: Made from purified silicon crystals.

-

Types:

-

Monocrystalline: Single-crystal structure, higher efficiency (18–22%), better performance in low light.

-

Polycrystalline: Multiple crystal grains, slightly lower efficiency (15–18%), lower cost.

-

-

Pros: Long lifespan (25+ years), high efficiency, proven technology.

-

Cons: More material and energy needed in manufacturing; rigid panels.

2. Cadmium Telluride (CdTe) Solar Cells

-

Material: Thin-film technology using cadmium and tellurium compounds.

-

Efficiency: 10–18% (improving with new research).

-

Pros:

-

Lower manufacturing cost than c-Si.

-

Performs better than silicon in hot climates and low light.

-

Uses less material (thin layer instead of thick wafers).

-

-

Cons:

-

Cadmium is toxic — requires careful recycling.

-

Shorter lifespan (typically 20–25 years).

-

Less common than c-Si, but popular in utility-scale projects.

-

Solar Cell vs Solar Module Efficiency

| Feature | Solar Cell Efficiency | Module Efficiency (with losses) |

|---|---|---|

| Monocrystalline | 22% – 26% | 19% – 22% |

| Polycrystalline | 17% – 20% | 15% – 17% |

| Thin-Film (CdTe etc) | 10% – 14% | 8% – 12% |

Note: Module efficiency is slightly lower due to wiring gaps, glass reflection, and encapsulation losses.

Capacity of Solar Modules

- Standard 60-cell module = 300W to 350W

- 72-cell module = 370W to 450W

- Half-cut 144-cell module = 450W to 600W+

Modern solar farms and rooftop projects use high-capacity bifacial or TOPCon/PERC modules for enhanced output.

Leave a Reply